Dhayari, Pune, Maharashtra

- GST NO. : 27AAGCN2273D1ZM

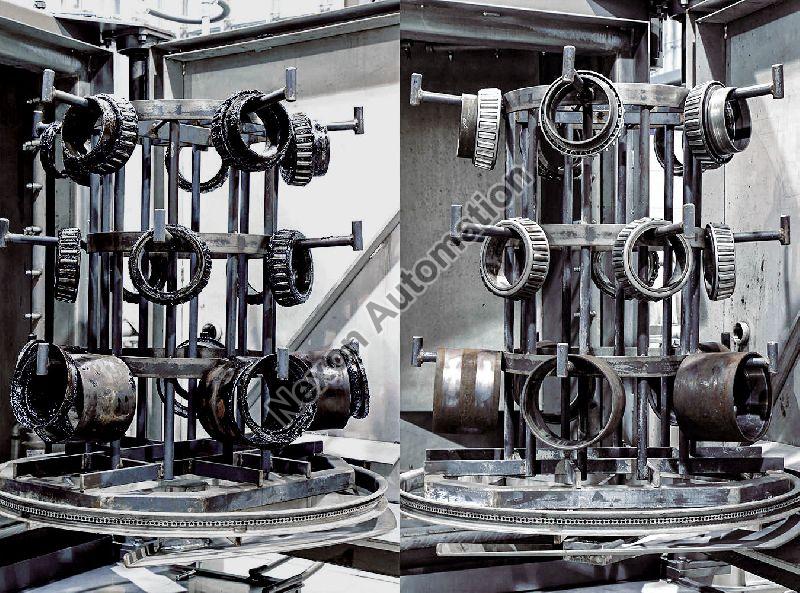

Component Cleaning Machine

Leading Manufacturers, Exporters, Wholesaler, Importer of Drum washing machine, Automatic Component Cleaning Machine, Automotive Component Cleaning Machine, Cabinet Type Component Cleaning Machine, Conveyorized Component Cleaning Machine, Industrial Component Cleaning Machine, Transmission Component Cleaning Machine, Axle Beam Cleaning Machine, Bearing Cleaning Machine, Conveyorized Bin Cleaning Machine and Rotary Type Bin Cleaning Machine from Pune.

MOQ : 1 1

| Business Type | Manufacturer |

| Country of Origin | India |

| Type | barre washing machine |

| Certification | Iso 9001:2008 |

| Weight | 1000-2000kg |

Preferred Buyer From

| Location | Worldwide |

Regardless of the model, each Nexon Machines’ barrel washing machine washer features:

- Each barrel, drum, and garbage can washer features a recirculating detergent wash tank and a separate, freshwater sanitizing rinse tank.

- Wash water is pumped through rotating or fixed spray arms fitted with high-velocity stainless steel V jets designed to cut and remove stubborn soils.

- Wash cycles are selected from a short, medium, or long sequence (4, 6, or 8 minutes) depending on soil conditions.

- Each wash cycle is followed by 30-second hot water, sanitizing rinse.

- The rinse water is routed back into the wash tank for reuse and to help freshen it.

- Filters collect debris and keep the nozzles from clogging.

- Electric, gas, or steam booster heaters maintain proper operating temperatures.

- Available with several options, including a steam extraction fan to vacate the steam before the door is opened, a protruding spray arm for bunged hole barrels, and assorted wash racks for lids, buckets, and utensils.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Type | Automatic |

| Certification | CE Certified |

| Voltage | 380V |

| Power | 27 KW |

| Driven Type | Electric |

| Brand Name | Skylark |

| Phase | 3 Phase |

| Air Pressure | 450 CFM |

| Material | SS 304 |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Skylark |

| Voltage | 420 V |

| Maximum Pressure Rating | 15 Bar |

| Air Flow Cfm | 450CFM |

| Air Pressure | 2.5 Millibar |

| Phase | 3 Phase |

| Power | 35 Kw |

| Frequency | 50 Hz |

| Capacity | 1000kg/hr |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Skylark |

| Phase | 3 Phase |

| Flow Rate | 150 LPM |

| Pressure | 12 Bar |

| Tank Capacity | 350 Litres |

| Temperature | 60 Deg.C |

| Material | Stainless Steel |

| Power | 12kW |

| Voltage | 280 V |

| Capacity | 500kg/hr |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Degreasing Machines |

| Operating Mode | Automatic |

| Machine Structure | Horizontal |

| Brand Name | Skylark |

| Power | 12.5 kW |

| Material | SS 304 |

| Certification | ISO 9001:2008 |

| Voltage | 380 V |

| Condition | New |

| Packaging Type | Wooden Box |

| Phase | Three Phase |

| Warranty | 1 Year |

| Usage | Industrial, Auto Part Clean |

| Pressure | High Pressure |

| Automation Grade | Automated |

| Weight | 2 Ton |

| Size | L-5500mm X W- 2700mm XH- 2300 mm |

| Cleaning Type | Degreaser |

| Capacity | 1500kg/hr |

Preferred Buyer From

| Location | Worldwide |

Convoyer type Compoenent Cleaning machine is specialy for mass production.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Skylark |

| Power | 12 kW |

| Voltage | 440 V |

| Automation Grade | Semi-Automatic |

| Power Source | Electric |

| Phase | 3 Phase |

| Frequency | 50 Hz |

| Material | Mild Steel |

| Capacity | 620kg/hr |

| Delivery Time | 1month |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Skylark |

| Power Consumption | 18 kW |

| Phase | 3 Phase |

| Automation Grade | Automatic |

| Cleaning Type | Hot Water Spraying |

| Air Pressure | 450 CFM |

| Ambient Temperature | 37 Deg C |

| Voltage | 230 V |

| Material | SS |

| Capacity | 100kg/hr |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Power Consumption | 24 Kw |

| Phase | 3 Phase |

| Cleaning Type | Hot Water Spraying |

| Automation Grade | Automatic |

| Voltage | 320 V |

| Material | SS |

| Capacity | 700kg/hr |

| Brand Name | Skylark |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Automatic |

| Material | SS |

| Vloltage | 380 V |

| Power | 10 kW |

| Usage | Industrial |

| Brand Name | Skylark |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loading Type | Front Loading |

| Phase | 3 Phase |

| Cycle Timing | 20 Sec. |

| Wash Capacity | 700bins/shift |

| Max Temperature | 55-60 Deg C |

| Water Consumption | 10 L per Hours |

| Material | MS and SS |

| Power | 30 kW |

| Voltage | 380 V |

| Brand Name | Skylark |

Preferred Buyer From

| Location | Worldwide |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Country of Origin | India |

| Certification | ISO 9001:2008 Certified |

| Weight | 4000-5000kg |

| Color | Customised |

| Voltage | 320 V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 18 Kw |

| Driven Type | Mechanical |

| Warranty | 1year |

| Brand Name | Nexon |

| Application | Plastic Bin Washing Machine |

| Power Consumption | 18 kW |

| Cleaning Type | Hot Water Spraying |

| Phase | 3 Phase |

| Material | SS |

| Capacity | 450kg/hr |

Preferred Buyer From

| Location | Worldwide |

Nexon rotary type Plastic bin washing machine is a specialized machine designed to clean bins in various industries, such as food processing, manufacturing, or waste management. These bins can be plastic, metal, or other materials and are typically used for storing or transporting goods.

The rotary type bin washing machine operates by using a rotating mechanism to thoroughly clean the bins. Here are the key features and functioning of such a machine:

-

Construction: The machine consists of a large cylindrical chamber or Basket that rotates horizontally or vertically. The drum is typically made of stainless steel and has openings or nozzles strategically placed to spray water and cleaning solution

-

Loading and unloading: Bins are loaded into the machine manually or automatically, depending on the design of m/c .The basket can accommodate multiple bins at once, allowing for efficient batch cleaning.

-

Cleaning process: Once the bins are loaded, the drum starts rotating. High-pressure water jets or spray nozzles are used to direct water and cleaning solutions onto the surfaces of the bins. The cleaning agents may include detergents, sanitizers, or disinfectants, depending on the specific requirements and the type of contaminants to be removed.

-

Scrubbing and rinsing: The rotating action of the drum ensures thorough coverage of the bins. As the bins rotate, brushes or scrubbers mounted inside the drum scrub the surfaces, dislodging dirt, residue, or other contaminants. The water spray rinses away the loosened debris, leaving the bins clean.

-

Drying: After the cleaning process, some rotary bin washing machines also have a drying stage. Hot air blowers or drying chambers may be integrated into the machine to remove excess moisture from the bins, ensuring they are ready for immediate use or storage.

-

Control system: The machine is typically equipped with a control panel or interface that allows the operator to set various parameters, such as cleaning time, water temperature, detergent concentration, and drying options. Some machines may have automated controls or programmable settings for efficient operationRotary type bin washing machines offer several benefits, including improved hygiene, reduced manual labor, increased productivity, and consistent cleaning results. They are especially useful in industries where large quantities of bins require regular cleaning to maintain cleanliness standards and prevent cross-contamination.